In modern cars, work managementengine is carried out by the electronic unit, which receives information about the health of its systems using appropriate sensors. The cooling system, designed to provide the optimum temperature mode of the motor, includes several such signal devices. One of these is a coolant temperature sensor (DUT). What this device is and what its functions are, we will discuss in this article. In addition, we will consider possible malfunctions of this cooling system element, as well as ways to diagnose and eliminate them.

The gauge of temperature of a cooling liquidis designed to obtain information about the temperature of antifreeze or antifreeze in the system and its subsequent transfer to the electronic control unit. Based on these data, the car controller regulates:

The principle of the sensor is quite simple. It is based on the properties of semiconductors to change their electrical resistance under the influence of temperature.

What is a temperature sensor? DUT consists of the following elements:

The coolant temperature sensor has twoelectrical contact, one of which is a body that closes to the ground, and the second - a "+", going to the electronic unit. The controller sends a voltage of 5 V to the DCT, which is transmitted to the operating element by means of a current-carrying spring. The semiconductor thermistor itself has a negative temperature coefficient, and when the coolant into which it is placed is heated, its resistance begins to decrease. At the same time, the voltage decreases. It is by its change that the electronic control unit calculates the temperature of the cooling liquid in the system.

Temperature sensor, thanks to its simpledesign, it breaks down quite rarely, but, if this happens, it is replaced with a new device. The sensor failure is easy to determine. Its failure is most often accompanied by certain symptoms that are inherent only to an inactive DETZH. What are these symptoms, read on.

Determine the malfunction of the coolant temperature sensor by the following symptoms:

The last fault can not beonly DETZH. If the cooling fan is not working properly, first check its electrical drive and the integrity of the wiring. Only after making sure of their performance, it can be concluded that in the engine overheating it is the temperature sensor that is to blame. DETZH can be both non-working and conditionally working.

Faults on the coolant temperature sensor include:

As you can see, there are not so many faults in DTEZ. In the first case, the sensor simply starts to lie, misleading the electronic unit. The latter, using inaccurate information, will be forced to make wrong decisions. From here and the difficult start of the engine, and a fuel overexpenditure, and untimely inclusion of the fan of a radiator.

Closure in the sensor occurs when deformation or destruction of its housing. This phenomenon is easily determined by the controller, which it sends the appropriate signal to the instrument panel.

Infringement of tightness of the case most often also occurs because of mechanical damage of the sensor, less often due to prolonged operation.

If there is no contact on the terminals of the LTP, the controller usually keeps the engine running in emergency mode, and the radiator fan works in a constant mode just in case.

The first three faults can not be eliminated. Here, the situation can be remedied only by replacement of the TSS. In the latter case, contact can be restored, which is not difficult. After this, it is necessary to double-check the efficiency of the cooling system.

Ensure that the sensor is defective or faulty.you can by its simple verification. But first you need to know something about the location of the TOT. Where there is a sensor for the temperature of the coolant in a particular vehicle, it is better to find out from the manual for its operation. The fact is that in different models it can have a different layout. More often, the DCE is installed on the inlet pipe of the cooling jacket of the cylinder head or on the thermostat housing.

It is important not to confuse the temperature sensora coolant with a coolant temperature sensor (DUTRO). The latter also serves to determine the temperature of the coolant, but its data are used solely to inform the driver.

Checking the DTTZ involves the dismantling of the sensor. To do this, disconnect the negative terminal from the battery and partially drain the coolant. After that, the connector on the housing of the DTEZ is disconnected. The sensor itself is unscrewed from the seat with a car key. The process opening is closed with a clean rag for the duration of the test to avoid moisture or debris entering the cooling system.

To test the sensor you will need:

Checking the sensor is to determineThe correctness of the graduation of the working element of the DTDE. What does it mean? This means that during the test it is necessary to determine how correctly the resistance of the thermistor changes with temperature.

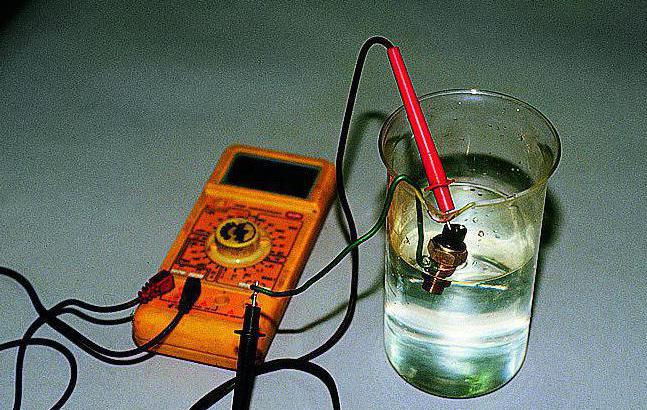

To begin with, the sensor contacts are connected to probesmultimeter, observing the polarity. The instrument is switched on in the ohmmeter mode. After this, DETSH together with the thermometer is lowered into cold water and read out their readings. Then the water is heated, continuing to make measurements.

Below is a table for calibrating the coolant temperature sensors.

Temperature, 0FROM | Resistance of working element, Ohm |

0 | 7300-7500 |

+20 | 2600-2800 |

+40 | 1000-1200 |

+60 | 500-600 |

+80 | 300-350 |

+100 | 160-180 |

If the resistance values of the DUT's work item are different from those in the table, the sensor is defective.

The sensor replacement process will not cause anydifficulties even in a person who has never been involved in repairing a car, especially if the device has already been dismantled for inspection. The only thing that needs to be done is to buy a new DETZH. The price of the coolant temperature sensors, depending on the brand of the machine, can vary between 300-800 rubles.

After buying DETZH, all you need to do ispre-check it in the manner described above (for greater confidence in its operability), and then screw it into place of the old one and connect the corresponding connector. After that, we top up the coolant, and also connect the ground wire to the battery. Then we start the engine, warm it up and observe the operation of the cooling system: whether the error on the instrument panel has disappeared, whether the radiator fan turns on in due time, whether the motor is running smoothly, etc.